The increase of 3D printers has allowed persons to make vehicle elements from scratch, varying from small-scale trim pieces to larger goods like bumpers. With the technology’s only restrictions getting price range and user creativity, the amount of likely creations is nearly countless. From the basics of 3D printing to the diverse kinds of filaments, here’s what you have to have to know about creating your personal 3D printed automobile pieces.

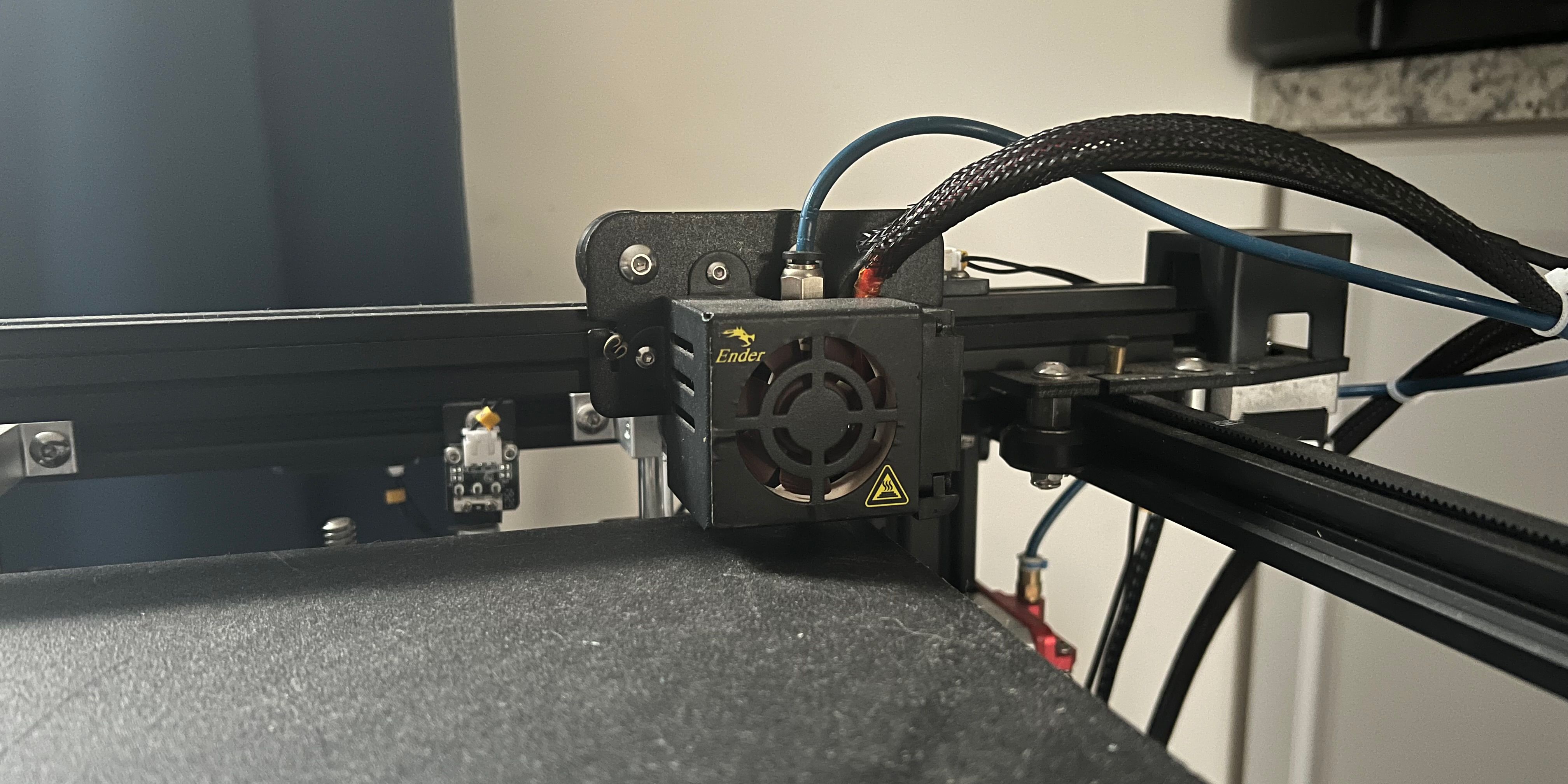

3D Printers and How They Operate

3D printers provide the potential to revolutionize how car pieces are manufactured. They can develop tangible objects by making them up layer by layer. Employing CAD software program or 3D scanners, objects can be built from scratch or recreated. Fortunately for those people who are not so relaxed planning their possess auto parts, sought-just after layouts are most probable now readily available on the internet, through Thingiverse and other internet sites giving free 3D print data files.

When you’ve designed or observed the file for the 3D model you want to print, it desires to be processed through a 3D slicer application such as Cura to prepare it for 3D printer. Slicing also provides information about the whole amount of filament and printing time needed for the particular file at hand.

From there, the resulting G-code, OBJ, or STL file can be exported to your 3D printer. In this article, the filament is sent by means of an extruder which sits on two or a few axes, enabling it to move around freely. Printed on a mattress, it builds up from the bottom to the remaining product. A heated bed may be demanded, relying on which style of filament is becoming made use of for the 3D print.

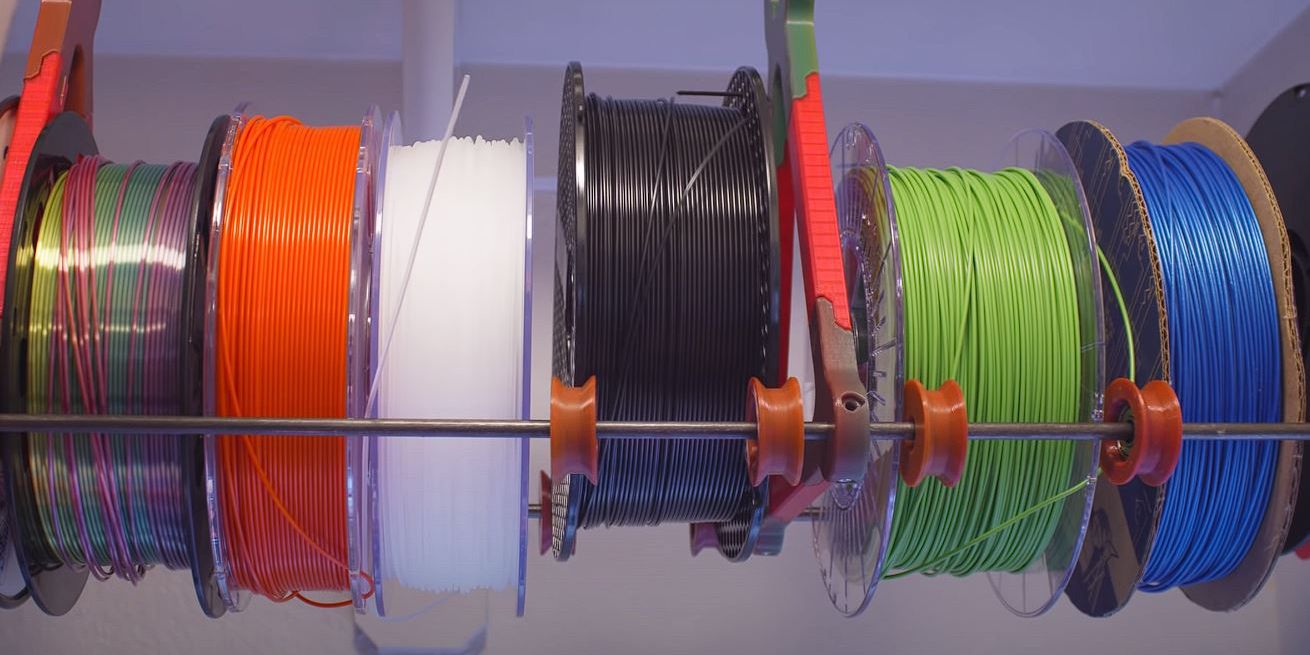

Distinctions in Filament

An vital component of 3D printing is the filament you opt to use. Different types of filament are much better for unique reasons, so deciding on the right 1 for your product is significant. Some frequently made use of filament elements include PLA and Abs, alongside with PETG, nylon, TPE, and Computer (polycarbonate).

The most commonly employed filament materials is PLA (polylactic acid), mainly because of to its simplified printing course of action. PLA is composed of renewable means like corn starch, doesn’t demand substantial temperatures to print properly, and is practically odorless. The reduce working temperature eradicates the require for a heated bed. Irrespective of the simplicity, there are a number of downsides to using PLA as your major filament. PLA has proven to be adaptable and somewhat fragile, producing it more suited for smaller versions and prototypes.

Stomach muscles (acrylonitrile butadiene styrene) is another normally applied content that is utilised mainly for products that have to have to endure lots of wear or tension. As opposed to PLA, Ab muscles requires a higher printing temperature and a heating bed, creating the printing procedure a minor much more elaborate. Due to the fact of its sturdiness, Ab muscles is acceptable for significant-have on objects and automotive trim items.

Polyethylene terephthalate (PET) is the most normally applied plastic in the entire world and is also occasionally utilized as a printer filament, even though its variant PETG is considerably much more prevalent. The “G” stands for “glycol-modified”, which finally can make the closing print much more exact, long lasting, and usable.

Sections Design and Recreation

There is a in the vicinity of limitless assortment of things that can be 3D printed, like automotive components for a passenger automobile. This is usually expected when a individual section is no longer accessible or is a far more fragile item that can shortly don out and will need changing.

Sections can be scanned with 3D scanners or designed with AutoCAD or related software program, enabling you to recreate or adjust the style of parts to your liking. 3D scanners can consider the kind of your cellular cellular phone or a dedicated piece of components. Goods as straightforward as visor clips and as intricate as connecting rods are choices with some design and style competencies and the support of a 3D printer.

Components like connecting rods need to have to be designed from more powerful elements these types of as carbon composite. However, most 3D printers will not be in a position to cope with this materials because they just can’t achieve the significant extrusion temperatures it wants. The abrasiveness of the content is also a challenge for most 3D printers, requiring a particular nozzle designed for the goal.

Custom Car Elements When You Want Them

With a 3D printer and a little imagination, the record of feasible creations is unlimited. This can dramatically minimize the overall cost of substitute vehicle sections and give you quicker access to them when you will need them.

As numerous motor vehicle lovers battle to retain more mature automobiles on the road, difficult-to-locate and no-more time-available areas can be recreated, earning any restoration procedure extra practicable.